Edilsystem has devoted special attention to the recovery of floors and roofs wooden materials, mainly as part of old and ancient buildings. An accurate research has enabled to identify a range of materials highly compatible with wooden material and able to guarantee excellent mechanical properties and durability, as well as unlimited duration in time.

In this sector, possession of special knowledge allows to identify even the most hidden causes of degradation and formulate a correct diagnosis, essential for a safe recovery.

Interventions

Fungicide and pesticide treatment

Executed by superficial impregnation or injection of wooden damaged elements

Reconstitution of matter-filling of holes formed by parasite attacks through epoxy formulated injections

Replacement or refurbishment of damaged areas

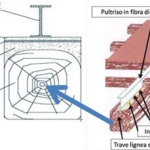

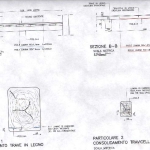

The operation consists in the reconstruction of wooden beam portions (primary and secondary) that are damaged due to water infiltration or parasites attack. It can be done either by replacement of another wooden element (fixed with fiberglass pins and epoxy materials) or by replacement of the damaged portion through the binding of stationary formwork, made of epoxy grout or low density pourable mortars, armed with fiberglass bars.

The operation consists in the reconstruction of wooden beam portions (primary and secondary) that are damaged due to water infiltration or parasites attack. It can be done either by replacement of another wooden element (fixed with fiberglass pins and epoxy materials) or by replacement of the damaged portion through the binding of stationary formwork, made of epoxy grout or low density pourable mortars, armed with fiberglass bars.

Work stages

Elimination of damaged parts from wooden beam. Load control and sizing definition of the armor with suitable sectioned fiberglass bars. Woodworm and anti-mold treatment by applying mono component synthetic resin by brush or spray, on all wooden elements, after accurately removing dust, fat substances and those materials which may affect a perfect anchoring of the resin.

Perforation of the wooden beam head and accurate blowing of holes so as to eliminate any possible residue of unstable materials that may affect adherence to wood in the subsequent processing stages.

Insertion of round fiberglass rods highly resistant to corrosion, made from unidirectional fiberglass impregnated with synthetic resins.

Insertion of round fiberglass rods highly resistant to corrosion, made from unidirectional fiberglass impregnated with synthetic resins.

Fiberglass rods grouting through gun injection of fluid bi-component epoxy resin, solvent-free, with good structural adhesion to wood and without shrinkage after curing.

Creation of a stationary wooden formwork of the same size that the beam to be repaired and injection of fluid bi-component epoxy resin, solvent-free, with good structural adherence to wood, without shrinkage after curing, loaded 1-5 with inert quartz aggregates (granulometry 0-2).

Wooden structures reinforcement and consolidation

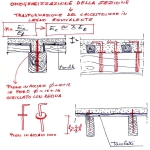

Structural reinforcements can be executed by the application of carbon fiber pultruded strips or

by insertion of fiber glass structural profiles, obtained by heated pultrusion processes and impregnation of thermosetting resins.

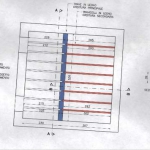

Wooden floors have two basic functions in a masonry building:

- carry vertical loads (permanent and accidental)

- connect the walls to ensure the box-like behaviour of the building

This second function is essential to ensure safety in case of earthquake, because allows transferring horizontal forces to the dividing walls (proportionally to their stiffness); however, it is not always present in old buildings, due to the scarcity of links between walls and beams.

The use of carbon polymer-matrix strips is particularly suitable for bending reinforcements, as they have better mechanical properties than those of harmonic steel.

They are specially indicated for primary or secondary beam bending reinforcements, and also:

- Minimize distortion

- Increase load bearing capacity

- Increase resistance to fatigue

- The requested reinforcement can be calculated

- Working time speeding

- Simple intervention without increasing permanent loads

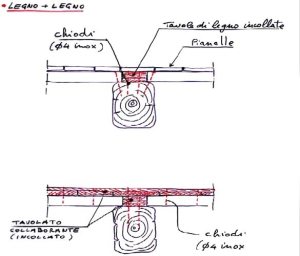

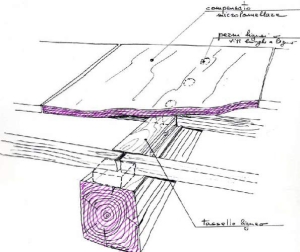

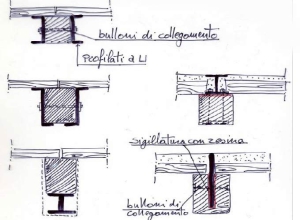

Primary and secondary beam system types of consolidation and reinforcement

“Camorcanna” vaults and plaster consolidation

The intervention consists in applying fiberglass sheets to consolidate the canes in the extrados part that acts as a framework between rafters.

To consolidate the “camorcanna” plaster, the plaster-barrel interface impregnates with special acrylic-based fluid mortars.